How Do Developed Film Capacitors Optimize Induction Heating Equipment?

Induction heating equipment is an extensively used technology that generates heat through electromagnetic induction; the working principle is per Faraday's law of electromagnetic induction. It states that a conductor subjected to a changing magnetic field induces an electromotive force (EMF) or voltage across the conductor, which results in the flow of electric currents, known as eddy currents, generating heat due to the material's resistance.

Film capacitors are vital in induction heating equipment and are utilized in the resonant circuits of the power supply due to their low loss characteristics, high stability, and excellent temperature performance. The function of film capacitors in the resonant circuit is to store and release electrical energy, maintaining the desired oscillation frequency and ensuring the system operates efficiently. In an induction heating system, film capacitors help filter high-frequency noise, correct power factors, regulate energy storage and voltage, and enhance system performance.

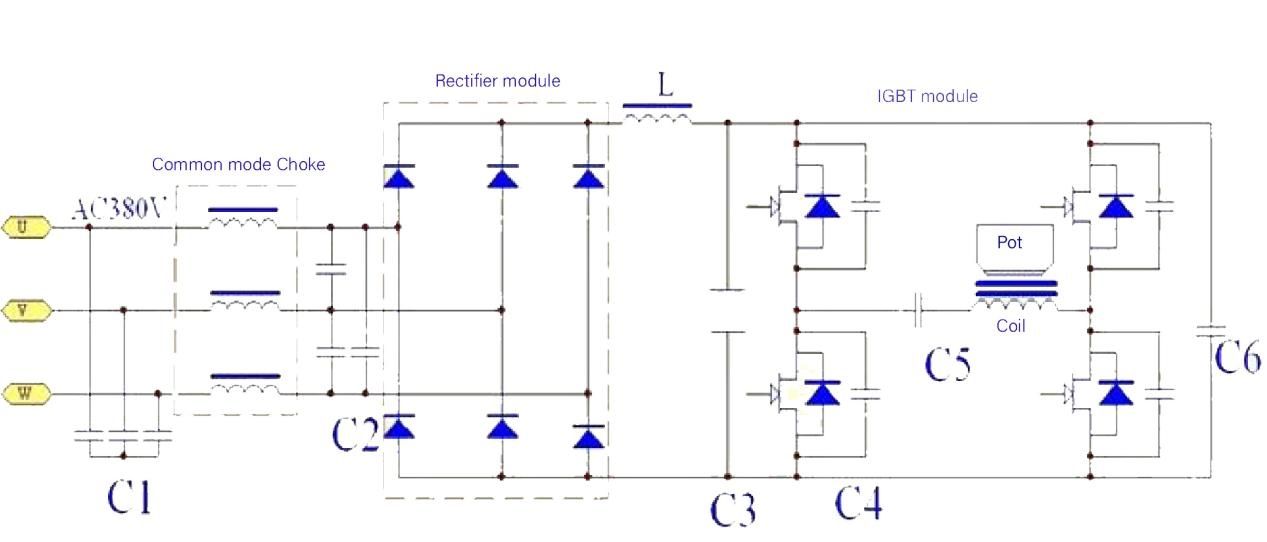

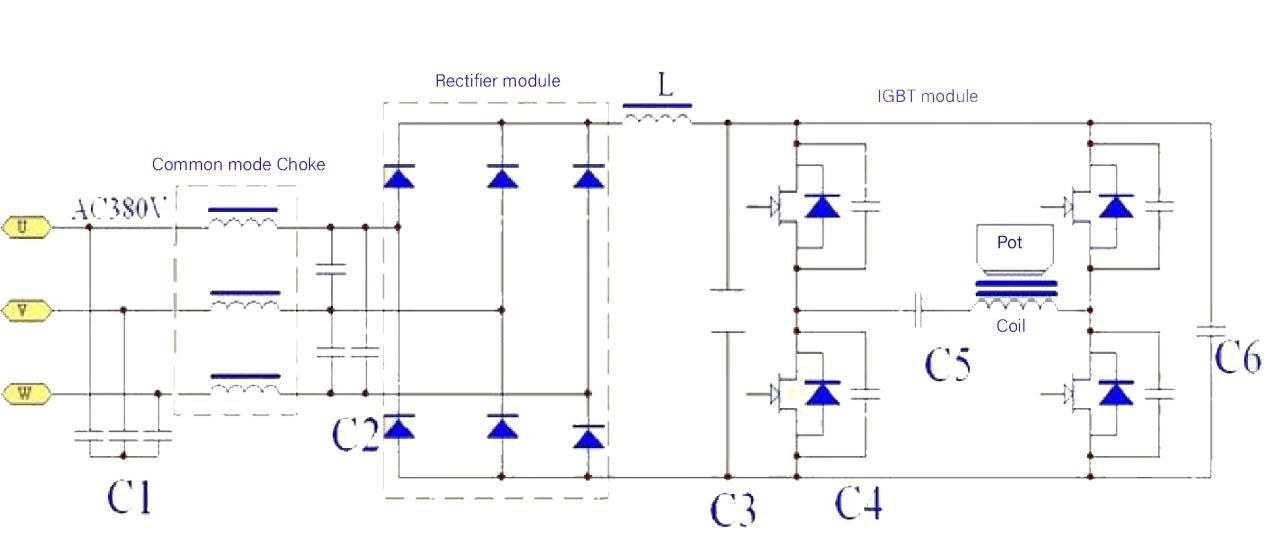

The Internal Module of the Induction Oven

The induction oven is a modern kitchen appliance that uses electromagnetic induction to generate heat for cooking purposes. At the heart of this appliance lies the internal module, which primarily consists of an induction coil, an electronic control unit, and a power supply.

ü The induction coil is a copper wire that, when subjected to an alternating current (AC), creates a magnetic field that induces current in the cookware, so causing it to heat up.

ü The electronic control unit manages the power settings and cooktop temperature, frequency, and amplitude of the AC voltage to regulate the amount of heat produced.

ü The power supply converts the household AC voltage to the required level for the induction process and ensures a reliable and efficient energy transfer.

Film capacitors are relevant to the operation of induction ovens since they are crucial in the power electronics and filtering of the appliance. In the power supply and electronic control unit, film capacitors smooth out the voltage waveform, reducing voltage ripple and transient voltage spikes, and help minimize interference, improve efficiency, and protect other components from damage.

The Function and Requirements of Capacitors

Capacitors, including film capacitors, are versatile components in electrical and electronic circuits, coming in various sizes and shapes and serving numerous functions, such as induction heating.

However, their core function is to store electrical energy between their plates, which allows them to serve as voltage sources, instantaneous current providers, noise filters, frequency harmonic blockers or eliminators, DC blockers, tuning devices, sensors, and circuit protectors from glitches. The energy stored in capacitors creates a potential difference across their plates, and they can easily charge and discharge to provide high currents in a short period of time.

As far as their technical requirements are concerned, key parameters include

ü Capacitance to represent a capacitor's ability to store electrical charge.

ü Voltage rating, which indicates the maximum voltage a capacitor can safely handle.

ü Equivalent series resistance (ESR), a measure of the capacitor's internal resistance.

ü Temperature coefficient, which describes the capacitance's dependence on temperature.

Furthermore, capacitors must meet size, form factor, and mounting style requirements, with surface-mount (SMT) and through-hole (THT) being common choices. The dielectric material affects the capacitor's performance characteristics, reliability, and lifetime, while tolerances, specified as a percentage, equally indicate the acceptable deviation from the nominal capacitance value. Last but not least, the operating temperature range and rated lifetime are fundamental factors in determining a capacitor's durability and suitability for specific applications.

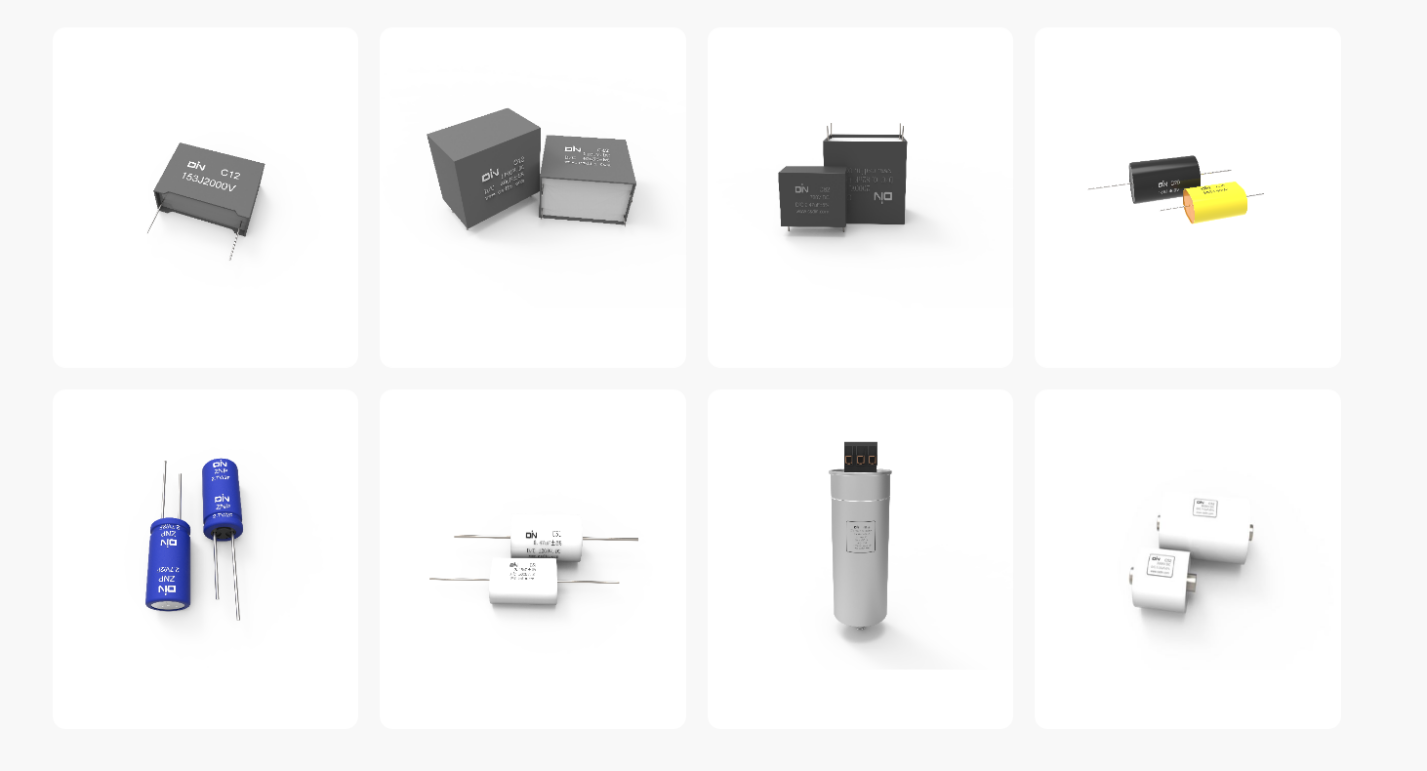

What DIN ELECTRONICS Has to Offer!

After going over the operating principle of induction heating equipment, the internal module of an induction oven, as well as the function and requirements of various capacitors, you would undoubtedly be thinking about a dependable provider of various types of capacitors, incorporating film capacitors such as polypropylene film capacitors and polyester film capacitors, which meet your general as well as customized requirements. We want to take this opportunity to introduce you to the distinctive capacitor series that DIN ELECTRONICS offer.

C1: MKP-X2

DIN ELECTRONICS offers MKP-X2 capacitors designed specifically for EMI suppression in induction heating equipment. With a capacity range of 3μF-10μF and rated voltages of 275V.AC-300V.AC, these capacitors are ideal for three-phase AC input filtering, helping to absorb ripples and improve the equipment's ability to resist grid interference. Moreover, these capacitors use a Y-type connection, with the common terminal suspended without grounding, ensuring effective electromagnetic interference suppression and absorption.

C2: Metallized Capacitors Series

Their Metallized Capacitors series is designed to enhance the equipment's ability to resist grid interference. With capacities ranging from 3μF to 10μF and rated voltages from 450V.AC to 500V.AC, these capacitors can be connected in a triangular configuration. The larger the capacitor chosen for this series, the better the suppression and absorption of electromagnetic interference, offering superior performance while maintaining capacitor life and preventing voltage breakdown.

C3: DC-LINK Capacitors Series

DIN ELECTRONIC' DC-LINK Capacitors series is designed for induction heating equipment rectification and DC link applications. These capacitors work with choke coils to form an LC circuit, converting pulsating DC into smooth DC for the subsequent inverter bridge and load. The capacitors in this series act as DC support, which absorbs ripple and completes the AC component loop. Selecting larger capacitance values for this series will enhance absorption effects, ensuring your induction heating equipment's safe and efficient operation.

C5: Snubber Capacitors Series

The Snubber Capacitors series from DIN ELECTRONICS is designed to protect power electronics devices, including IGBTs (insulated-gate bipolar transistors), from voltage transients and spikes. These capacitors absorb the high harmonic currents and peak harmonic voltages generated during high-speed switching, preventing self-excited oscillations in the DC bus circuit. Surely, this helps to ensure the safe use of IGBTs and other power electronics components, prolonging their service life and enhancing the overall performance of your induction heating equipment.

About DIN ELECTRONICS

Founded in 2001, the national high-tech enterprise, DIN ELECTRONICS, specializes in producing film capacitors, along with various other types, using advanced equipment and independent reliability laboratories. Their R&D team works tirelessly to stay at the forefront of technology, rapidly designing and manufacturing cost-effective products in collaboration with customers. DIN ELECTRONICS's high-quality capacitors serve various industries, including electric power grids, smart metering, renewable energy, wireless charging, and intelligent households.